Top 5 Reasons Why Xcentric Is a Trusted Partner for Injection Molding

Our scientific approach to injection molding differentiates Xcentric in the marketplace. We developed a software expert system to predict the appropriate process parameters for each project based on years of process data and collective team experience captured with every project.

Then, we apply this system to every new project to help plan, design, execute, and monitor the injection molding process. Our process engine is used during the production part run to provide technicians with the optimal machine parameters to mold a high-quality part, even in single-digit quantities.

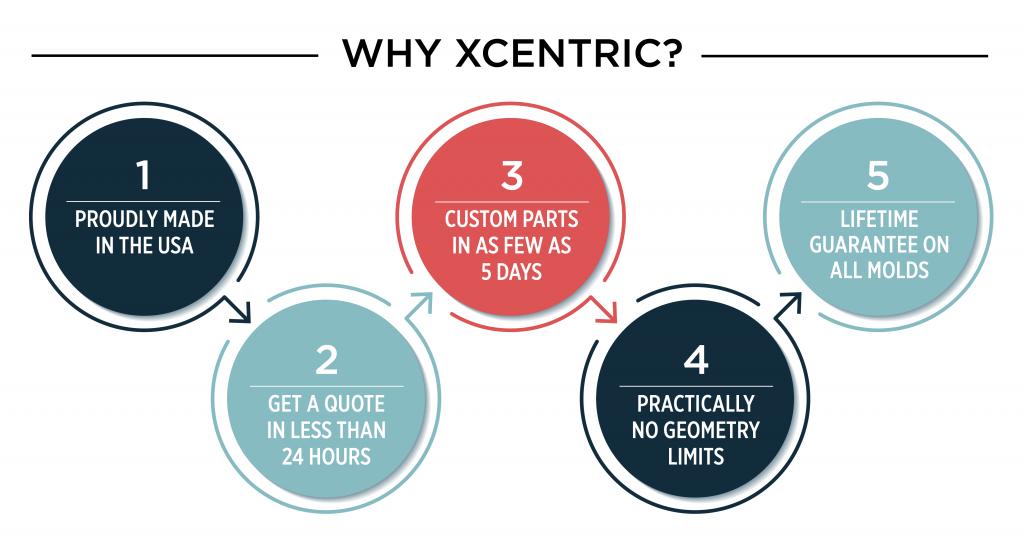

Start Your Quote1. Proudly made in the USA

We can help to expand your supply chain with two MI-based manufacturing facilities! Shorter logistics means faster turnaround and real-time access to on-site subject matter experts who support your project from design through production.

On-Site Subject Matter Experts

On-site subject matter experts provide a design review and manufacturability analysis for each order. We confirm whether the design is appropriate and proceed directly to the mold design step.

However, if we determine that a part cannot be manufactured, for any reason, we provide clear feedback and suggestions for keeping production on track.

If we are unsure of being able to deliver technically or in the desired delivery time frame, we inform our clients immediately.

Access the latest technology

Located in Clinton Township, MI and Shelby Township, MI, our state-of-the-art facilities are fully equipped with the latest technology and capable of manufacturing precision molds and injection-molded parts in a matter of days. And, because of our fully integrated proprietary ERP system, we can provide timely updates on every project at any phase. In addition, we can meet requests for production part reorders in a matter of hours, capacity permitting.

2. Get a Quote in Less Than 24 Hours

Our on-line customer portal is designed to guide you through every step of the quoting process, fast.

From design tips to material selection suggestions, our Technical Specialists are highly experienced in all areas of the plastic injection molding process. We listen to our customers’ objectives and formulate a project plan best suited to achieve the desired end result.

3. Custom Parts in as Few as 5 Days

Xcentric is one of the fastest suppliers of complex, custom injection-molded parts in the world. We owe this to our amazing team of subject matter experts, modern systems, and streamlined processes.

Xcentric Process Engine

Our scientific approach to injection molding via our proprietary process engine truly differentiates Xcentric in the marketplace. The process engine is an expert software system that predicts the appropriate process parameters for each project based on years of process data and collective team experience.

We then apply this system to every new project to plan, design, execute, and monitor the injection molding process. Our process engine is used during the production part run to provide technicians with the optimal machine parameters to mold a high quality part, even in single digit quantities.

4. Practically No Geometry Limits

Like your custom plastic parts, not all fast-delivery injection molding companies fit the same mold. We connect with on-site mold makers who help to ensure parts are manufactured to expectations.

At Xcentric, “no geometry limits” means we design molds that will achieve any final geometry that can be injection molded. That means parts can be produced with common complex features such as undercuts, internal and external threads, thin wall molding, insert molding and much more.

We do our utmost to achieve the design intent of our clients with few if any modifications. However, in the event that a change is required to improve the aesthetics, dimensional accuracy, or other aspect of the molded component, we work closely with the client to minimize time and cost impacts.

5. Lifetime Guarantee on All Molds

Xcentric is proud to be your one-stop resource for plastic injection molding solutions. We have the capacity and expertise to serve as a scalable manufacturing partner—whether you need prototype, bridge, or production parts.

Simply put, we are here to meet your production needs, any time. You own the mold, and Xcentric will maintain it for as long as you need parts.