Our part design guides will help you to address a variety of design challenges. For example, optimizing your part designs for manufacturability, cost, and time to market.

To speak with one of our experts about a design challenge, please contact Xcentric’s design consultants.

Video Resources: Injection Molding Processes

Understanding types of injection molding process can help to avoid some design challenges early in the process. For instance, three widely used processes are insert molding, overmolding, and undercuts.

Additional Design Guide Resources

At Xcentric, our goal is to provide designers easy access to resources and subject matter experts. We believe the fastest way to market is to prevent issues in the early stages of the process.

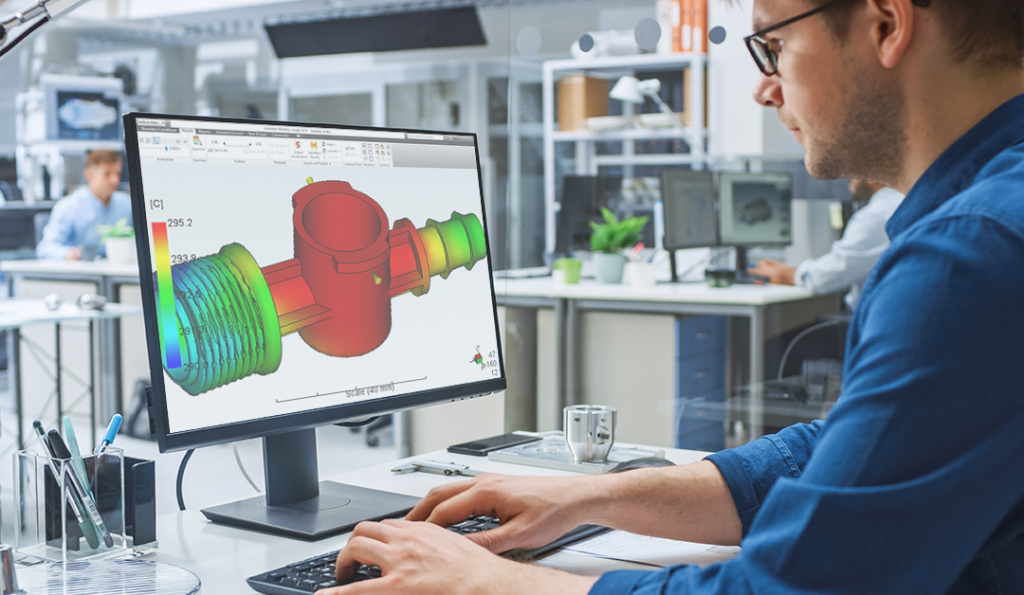

Mold Flow Analysis For Injection Molding

Designing parts for the injection molding process? Then consider running mold flow analysis before cutting the mold. For one thing, it can help to predict design flaws before production begins.

Designing for Manufacturability eBook

Design tips and injection molding best practices. Learn how to optimize plastic part designs from concept through production. Eliminate unneeded costs and reduce time to produce custom injection-molded plastic parts.

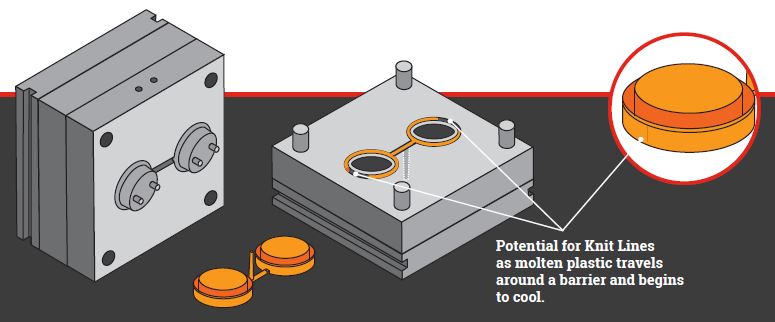

How To Eliminate Knit Lines

Knit lines form when two or more plastic flow fronts collide and solidify or “knit” during the molding process. Knit lines don’t always compromise the structural integrity of plastic parts. Still, they are almost always a cosmetic issue.

Contact Xcentric Design Consultants

Ready to get started with an injection molding project?

Start Your Quote