GET A QUOTE Thank You For Your Interest Click on the button below to download the design guide. Want more information? Let’s set up

Search Results for: wall thickness

Wall Thickness Guide for Injection Molding LP

GET A QUOTE Deign Guide Wall Thickness Guide for Injection Molding GET A QUOTE Draft Angle in Injection Molding Optimizing wall thickness for your

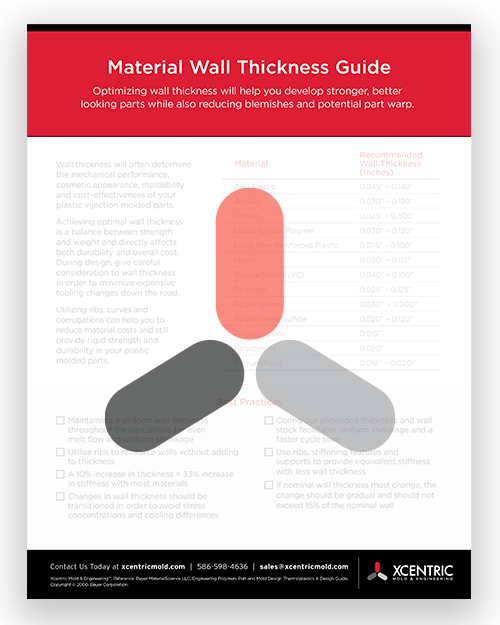

Material Wall Thickness Design Guide

Material Wall Thickness Guide Wall thickness will often determine the mechanical performance, cosmetic appearance, moldability, and cost-effectiveness of your plastic injection molded parts. Get

Wall Thickness Guide For Plastic

Part Design

Maintaining uniform wall thickness throughout your plastic injection molding part design is critical. Without uniform wall thickness, many issues can occur such as sink, warping, …

Wall Thickness Chart for Common Plastics

Top 5 Design Tips Maintain a uniform wall thickness throughout your parts design Thick wall design is prone to warp or other cosmetic issues

Ribs Design Guide LP

GET A QUOTE Design Guide Designing Ribs for Injection Molding GET A QUOTE Draft Angle in Injection Molding Want to improve your part’s strength