Plastic injection molding cost- Factors that will affect it significantly

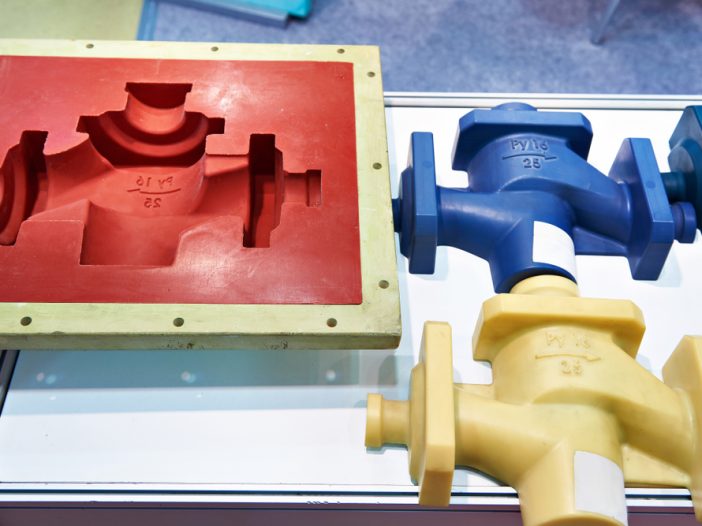

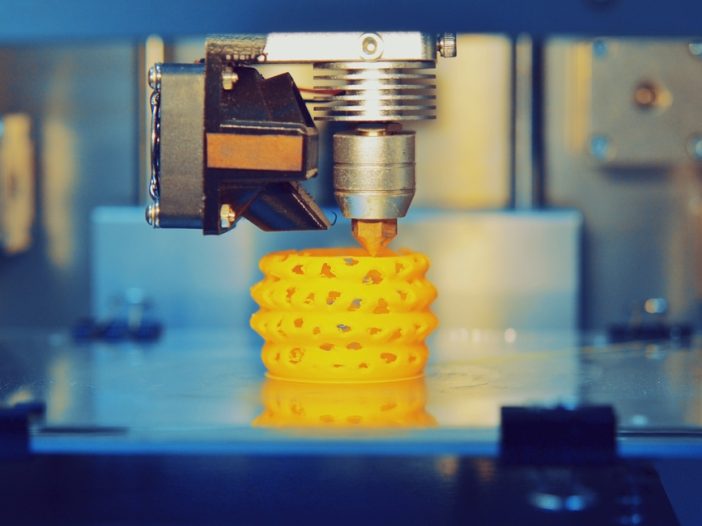

Plastic Injection Molding Cost-What Factors Will Affect It Significantly? Injection molding is one of the common manufacturing processes where molten plastics are injected into

Continue Reading